AWS

Eliminating human error from pilot signalling

The equipment in the track consists of a protective ramp preceding a Permanent Inductor (AWS3) and an Electro Inductor (AWS1).

AWS acts as a backup indication, reducing human error

The Permanent Inductor has its North Pole uppermost and this magnetic field by itself gives a “caution” indication to the driver. The Electro Inductor (AWS1), when energised, has its South Pole uppermost and this South Pole following the North Pole of the permanent inductor gives a “Clear” indication to the driver. On bi-directional lines, special permanent inductors called Suppressor Inductors(AWS2) may be used to prevent a train receiving A.W.S. indications at a signal for the opposite direction to which the train is travelling. These inductors have a permanent inductor and, in addition, a suppressing coil which, when energised, diverts the magnetic flux, suppressing any indication to the train.

For detecting the magnetic fields produced by the AWS track-mounted units, please see MRD’s MagSense.

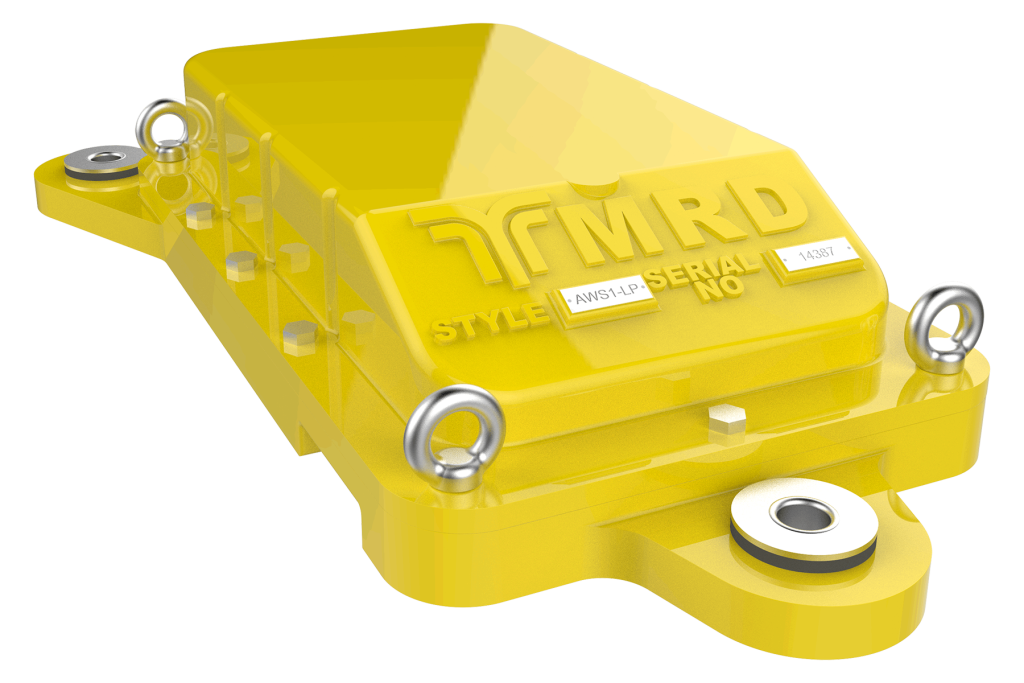

Low Profile AWS 1

The Automatic Warning System (AWS) is a safety system consisting of 3 different magnet types (AWS 1, 2 and 3) and a locomotive-mounted detector (MagSense), designed to aid drivers in observing the fixed signals, particularly under adverse weather conditions, and is supplementary to the fixed signals which the driver must observe.

The Electro Inductor (AWS1), when energised, has its South Pole uppermost and this South Pole following the North Pole of the permanent inductor gives a “Clear” indication to the driver.

| Product | Part Number |

|---|---|

| LP AWS 1 | AWS1-LP |

Low Profile AWS 2

The Automatic Warning System (AWS) is a safety system consisting of 3 different magnet types (AWS 1, 2 and 3) and a locomotive-mounted detector (MagSense), designed to aid drivers in observing the fixed signals, particularly under adverse weather conditions, and is supplementary to the fixed signals which the driver must observe.

On bi-directional lines, special permanent inductors called Suppressor Inductors (AWS2) may be used to prevent a train receiving A.W.S. indications at a signal for the opposite direction to which the train is travelling. These inductors have a permanent inductor and, in addition, a suppressing coil which, when energised, diverts the magnetic flux, suppressing any indication to the train.

| Product | Part Number |

|---|---|

| LP AWS 2 | LP AWS 2 |

AWS 3

The Automatic Warning System (AWS) is a safety system consisting of 3 different magnet types (AWS 1, 2 and 3) and a locomotive-mounted detector (MagSense), designed to aid drivers in observing the fixed signals, particularly under adverse weather conditions, and is supplementary to the fixed signals which the driver must observe.

The equipment in the track consists of a protective ramp preceding a Permanent Inductor (AWS3) and an Electro Inductor (AWS1). The Permanent Inductor has its North Pole uppermost and this magnetic field by itself gives a “caution” indication to the driver.

| Product | Part Number |

|---|---|

| AWS 3 | AWS3 |

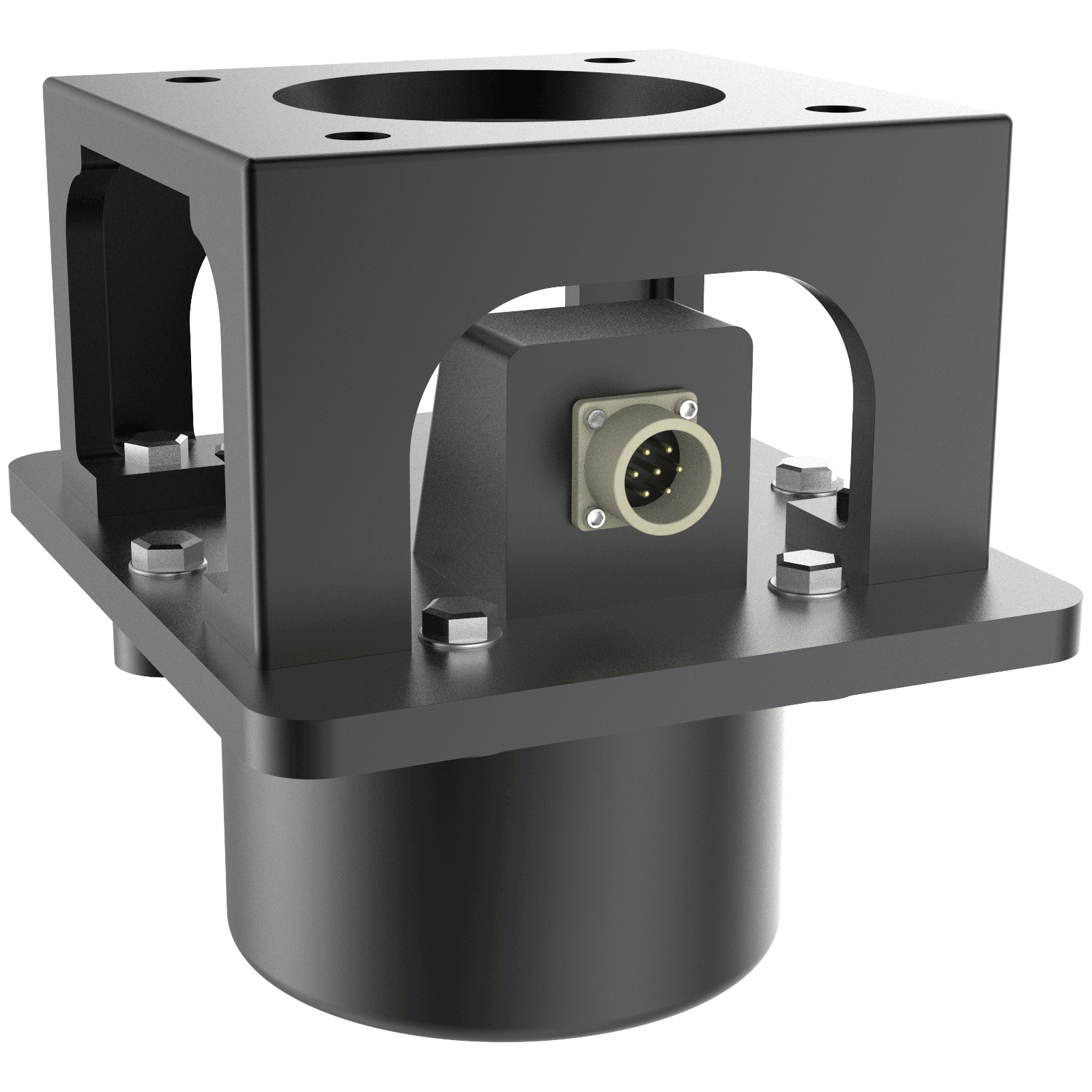

MagSense

MRD’s MagSense track magnet receiver has been designed for maximum reliability, to detect track magnets used in Station Protection, Automatic Power Control and Automatic Warning Systems. The detector’s operation is easily configured and calibrated to latch at the specified field strengths using the provided calibration software. There is no need to open the enclosure to adjust pots. The mode of operation can also be customised to suit specific customer requirements.

| Product | Part Number |

|---|---|

| MagSense New with Cannon Connector | MagSense-C |

| MagSense New with Marachel Connector | MagSense-M |

| MagSense Retro with Cannon connector | MagSense-RC |

| MagSense Retro with Marachel Connector | MagSense-RM |

FAQ

TrackSense’ modular design means you can purchase only what you need and expand your site with more I/O extender cards at any time to monitor more/different assets.

Whenever we bring out a new module, your current hardware won’t be made redundant – you can simply slot the new module in and upgrade your site.

Hardware repairs and replacements are made simple and generally won’t even require any site down-time. All you need to do is unplug the damaged module and replace it with new/repaired hardware.